Your industry, our know-how

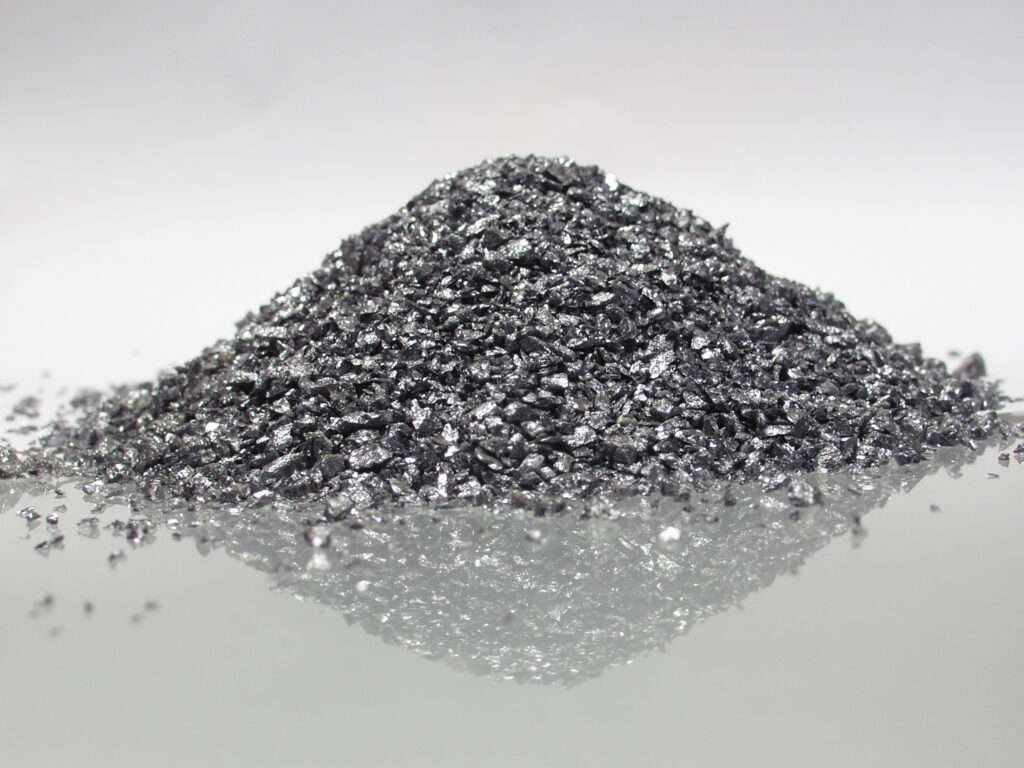

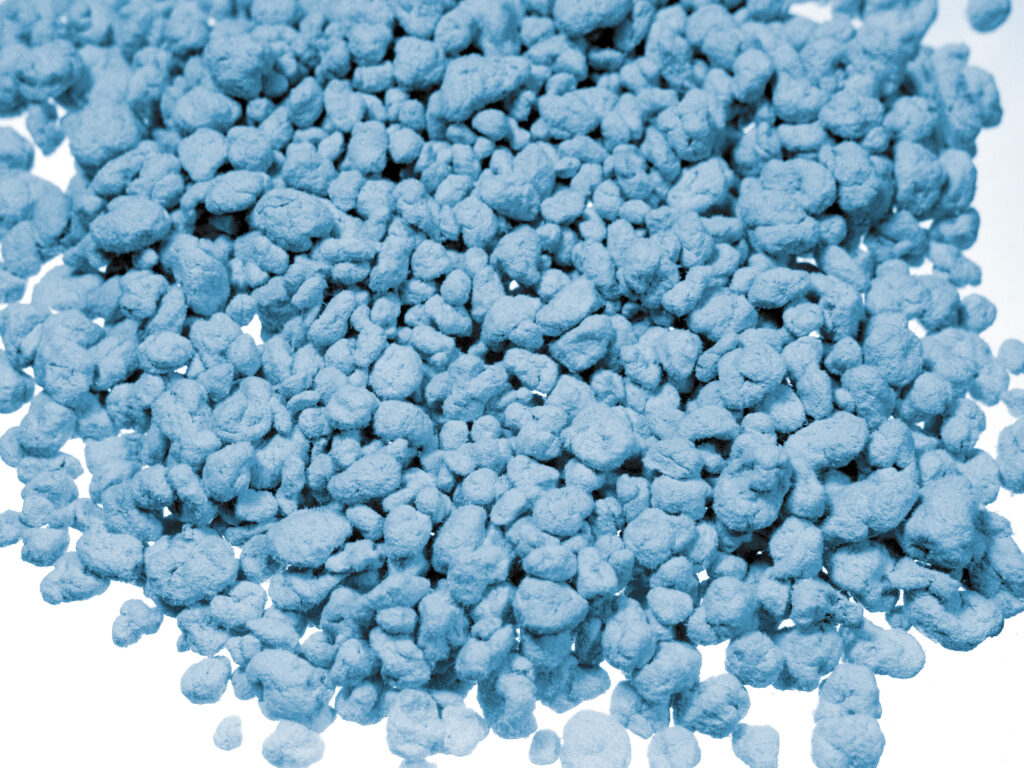

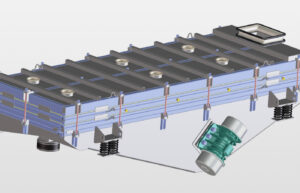

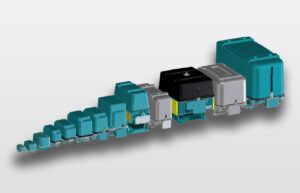

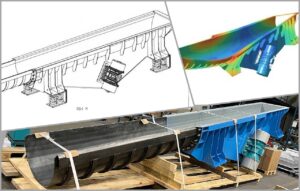

AViTEQ is a renowned expert in the field of bulk material handling specializing in conveying and screening technology with a history of over 80 years. Our promise: Efficient solutions for the transportation and sorting of bulk materials in almost every industry. As a manufacturer, we offer you customized vibratory machines that meet the highest standards, protect the product and ensure process continuity.

Our satisfied customers say:

We really enjoy working with AViTEQ , as they always provide us with excellent advice and support, from the quotation to order processing. The vibratory conveyors supplied meet our desired requirements and have always satisfied us and our customers. We have always been able to rely on AViTEQ throughout the years of our partnership.

Our product categories

At AViTEQ, we have been working on a wide variety of projects for many decades and are always looking for the best possible solution for our customers. Find out more about our different product categories here.

Brochures and further information

Are you looking for more information about us and our company? Then you will find a list of various documents to download here.

Our download area

Our brochures and further information are available for download as PDF files. Operating instructions are available on request.

Simply get in touch with us

As a specialist for individual solutions, we know that nothing can replace direct contact. We are therefore happy to answer your questions, projects and concerns personally. Simply use our contact form - we will get in touch with you as soon as possible.